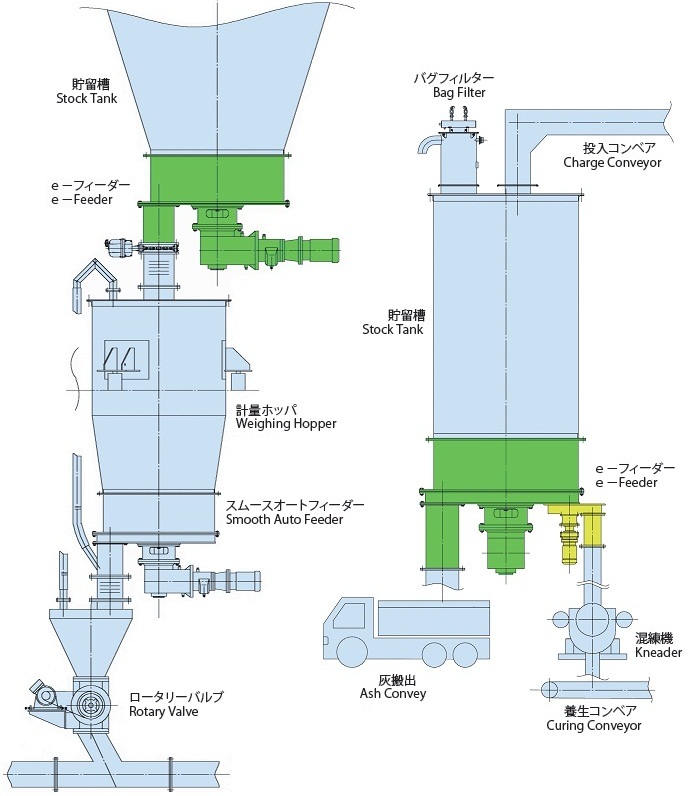

For Discharge of Powder Materials from Large Diameter Silo

Realizing stable feeding for powder and granular material required large bore outlet of storage silo.

Secures Stable Output Functionality

By integrating a volumetric feeding table with high quantitative performance, the e-Feeder ensures a higher level of stable output in comparison to traditional discharger.

Uses Less Space

The e-Feeder is compact in comparison to traditional discharger, allowing for a reduction in the amount of space used by the equipment.

Energy Efficient

This product has a smaller agitator cylinder than traditional discharger, making for a simple, saving power consumption design.

Use of the e-Feeder increases equipment-related energy efficiency.

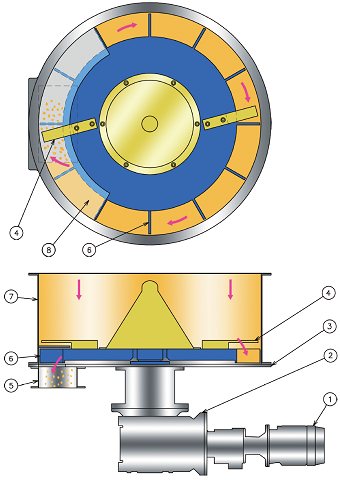

Dual-Direction Output is Possible

As the e-Feeder is capable of continuous stable dual-direction output from a single storage silo, it helps to save space.

Capable of Being Used in Various Equipment Types

As it is possible to integrate a quantitative feeder into the dual-direction output, feeding and output corresponding to the requirements of latter-stage equipment is possible.

Capable of Feeding Many Types of Powders and Materials

Through the combination of the feeding and agitating mechanisms, the e-Feeder is capable of feeding various types of materials including those that are non-uniform in shape, as well as powders with high adhesiveness or fluidity.

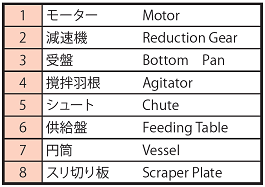

Powders collected in the storage tank are loosened by the agitator blades (4), and in a uniform and un-compacted state are fed into the feeding table (6).

Powders fed in this manner are divided into uniform volumes by the scraper plate (8) and are then discharged into the chute (5).

Adjustment of the feed rate is performed by varying rotation speed at the inverter.

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|

|---|---|---|---|

| EF-10 | 10m3/h | 2.2kW | 1100kg |

| EF-12 | 15m3/h | 3.7kW | 1300kg |

| EF-14 | 20m3/h | 3.7kW | 1500kg |

| EF-16 | 25m3/h | 5.5kW | 1800kg |

| EF-18 | 35m3/h | 5.5kW | 2200kg |

| EF-20 | 45m3/h | 7.5kW | 2700kg |

| EF-24 | 60m3/h | 7.5kW | 3000kg |

- 上記、仕様以外にEF-24を越える大型機も製作可能です。

- We can also manufacture large-scale models that exceed the specificationsof the EF-24 unit described above.

Applicable Powder Material List for Feeders

| 消石灰 | Slaked lime | 脱水ケーキ | Dewatered sludge |

| 生石灰 | Quicklime | 石膏ボード粉 | Gypsum board powder |

| セメント | Cement | 肥料 | Fertilizer |

| ウェット活性炭 | Wet activated carbon | 飼料添加物 | Feed grain |

| 炭酸カルシウム | Calcium carbonate | パルプ粉 | Pulp powder |

| 水酸化アルミニウム | Hydrated alumina | 乾燥汚泥 | Dry sludge |

| タルク | Talc | 焼却灰 | Burned ash |

| オイルコークス | Oil cokes | 溶融飛灰 | Melted fly ash |

| 石炭化合物 | Coal compound | 重油灰 | Heavy oil ash |

| メタバナジン酸アンモニウム | Sodium metavanadate | 硫酸第一鉄 | Ferrous sulfate |

| ベンガラ | Jewelers’ rouge | AL系無機物 | AL system inorganic substance |

| 食塩 | Salt | 活性炭 | Activated carbon |