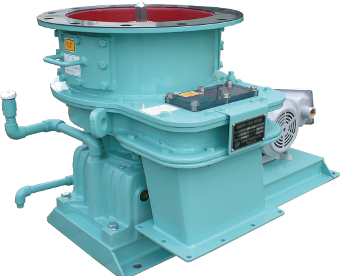

SGF-CSGF Type Smooth Auto Feeder

For Feeding Without Deformation of Particles

Features

■ The amount of deformation to the raw materials is extremely minimal.

Since it does not perform levelling motion like the impeller type, the material is discharged while maintaining its original shape.

By using a step type feeding table and a deflection plow(scraper) together, occurrence of bite, wear is less occurred and can be discharged without changing the shape of the material.

■ SGF/CSGF achieves continuous feeding without pulsation.

SGF/CSGF achieves continuous feeding without pulsation with a deflection plow.

■ SGF offers broad feed rate setting

By combination of the inverter and the scraper adjustment handle, SGF achieves a broad feed rate setting. The amount of material feeding can be controlled by changing the depth of the scraper manually(optional). The feed rate can also be controlled by using a inverter to adjust the speed of the feeding table.

■ Bridgeless design!

CSGF consists of a supply unit and a agitation unit. Since it is possible to design that a feeding table with a small diameter is arranged outside the diameter of the silo opening, stable feeding is possible even if feeding amount is small.(CSGF Type)

Structure description

【Overview】

Smooth auto feeder “SGF type” is a quantitative feeder that enables continuous feeding without changing the shape of granular, flake, pellet, or bulk material.

With combination of step type feeding table and scraper, it is possible to feed continuously to the downstream process without generation of material bite and abrasion. Therefore, our feeder is famous as “feeder without pulsation”.

It is possible to select “SGF type with Single-axle” or “CSGF type with Double-axle” according to the application and powder properties.

【Structure】

The powder from the upstream equipment (e.g. Silo) is charged to the feeding table in a uniform condition without consolidation by the Agitator①.

The raw material charged to the Feeding Table⑤ is levelled to a certain amount and then cut along the Horizontal Scraper⑥ to the Chute⑦ section.

By combination of the inverter and the Horizontal Scraper⑥ adjustment handle(optional), SGF achieves a broad feed rate setting.

| 1 | Agitator |

| 2 | Lower Vessel |

| 3 | Bottom Pan |

| 4 | Reduction Gear |

| 5 | Feeding Table |

| 6 | Scraper |

| 7 | Chute |

Specification

| Feed rate | Motor Power | Weight | |

|---|---|---|---|

| SGF-50 | 280L/h | 0.4kW | 120kg |

| SGF-100 | 600L/h | 0.75kW | 200kg |

| SGF-200 | 2m3/H | 1.5kW | 350kg |

| SGF-300 | 6m3/H | 2.2kW | 600kg |

| SGF-400 | 13m3/H | 3.7kW | 1000kg |

| SGF-500 | 30m3/H | 5.5kW | 1400kg |

| SGF-600 | 60m3/H | 7.5kW | 2300kg |

| SGF-700 | 150m3/H | 11kW | 3300kg |

| CSGF-10 | 6L/h | 0.2kW | 50kg |

| CSGF-20 | 12L/h | 0.4kW | 75kg |

| CSGF-30 | 130L/h | 0.75kW | 90kg |

Applicable Powder Material List for Feeders

| Flux | Coal |

| Aluminum | Dried wood activated charcoal |

| Wax | Rider coal |

| Silica | Burned ash |

| Titanium oxide | Dried sludge |

| Ferrite | Broken synthetic rubber |

| Cyanogens | Carbon minute powder |

| Sodium carbonate | Detergent |

| Graphite | Clay |

| Granular red oxide | Bisphenol |

| Silica | Meat and bone meal |

| PET resin | Delipidated Sugar |

| Polymerization inhibitor | Urea |

| Phenolic resin pellet | Spheroidal activated carbon |

| Resin pellet | Ferroboron |

| Vinyl chloride pellet | Aluminum alloy |

| Synthetic rubber pellet | Nylon |

| Plastic pellet | Chemical fertilizer |

| Scandium pellet | Tetoron flake |