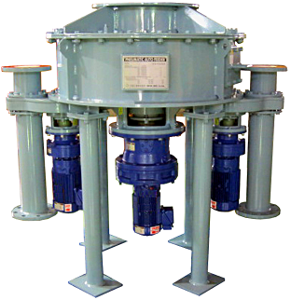

NP Type Pneumatic Auto Feeder

Multi directional volumetric feeder with individually-controlled feeding system!

Features

1. Realizes Multi-Directional Quantitative Feeding (Blowing)

Pneumatic auto feeder “NP type” is a multi directional pneumatic conveying quantitative feeder that enables continuous feeding of powder in multiple directions (2 to 6 directions) from a single stored silo.

2. Capable of Individual Feed Rate Adjustment

NP has independent feeding units, it is possible to adjust the feeding amount individually according to the downstream equipment, so it is possible to downsizing of the equipment.

3. Capable of Combining Pneumatic Transport and Gravity Transport Methods

NP can also offer a multi purpose feeder that integrates pneumatic convey unit and discharge unit in one equipment. In fact, NP can respond flexibly to customer demand.

Structure description

【Overview】

The pneumatic transport system can configure the bend to fit around existing devices and provides more flexibility than other feeding system that has a linear transport path. This also means that the pneumatic transport system occupies less space than an equivalent feeding system. Unlike other discharge system, the pneumatic conveying system is completely sealed so that it can contain fine powder without contamination in the pneumatic system.

NP can be made simple!

Since NP can discharge the powder directly to the pneumatic conveying line, Rotary Valve and deaeration chamber are unnecessary.

NP has an advantage that the impeller(Feeding table) is directly exposed to the pneumatic conveying line. That means that the NP can quantitatively deliver the powder directly to the conveying line. Further more, by supplying the powder directly to the conveying line, powder is not accumulated because it is cleaned with conveying air.

See also PS Type(Single Directional) and NPS Type(Micro Pneumatic Feeding).

【Structure】

The powder from the upstream equipment(e.g. silo) is relieved vertical pressure by the Spout⑧. Therefore, the powder is filled in the Feeding Table④ by Agitator⑦ with less consolidation.

The powder is leveled by the depth of the impeller of the rotating Feeding Table④ and the Feeding Table④ is directly exposed to the pneumatic conveying line. That means that the NP can quantitatively deliver the powder directly to the conveying line.

Feed rate can be adjusted by changing the motor rotation speed with the inverter.

| 1 | Agitator Motor |

| 2 | Feeder Motor |

| 3 | Inlet |

| 4 | Feeding Table |

| 5 | Outlet |

| 6 | Agitator Vessel |

| 7 | Agitator |

| 8 | Spout |

| 9 | Inlet Pipe |

Pressure Balancer (Patent Number 3803040)

We offer the best solutions to prevent trouble, combing a wide variety of design plans.

An extremely important aspect of the pneumatic transportation of powders is the balance of the pressure inside the transport piping at the feeder exit, and the powder seal pressure inside the silo.

If the pressure inside the transport piping at the feeder exit greatly exceeds the powder seal pressure inside the silo, there is a possibility that the pressure balance required for stable pneumatic transport will be disrupted and air injected into the inside of the feeder, impacting quantitative feeding functionality. There is also a possibility that flushing into other system’s transport piping will be induced.

We has developed a Pressure Balancer that contains a mechanism that adjusts the internal transport tube pressure in the transport piping to the correct value. The Pressure Balancer makes use of the total of air extensive experience and accomplishments and has been exhaustively tested in-house.

The Pressure Balancer uses the ejection effect to lower the pressure of the interior of the transport piping, and is a device that is capable to adjusting the pressure to the correct value.

Specification

Feed rate | Motor Power | Weight | ||

|---|---|---|---|---|

| Feeder Motor | Agitator Motor | |||

| NP-30-2 ~ 6W | 70L/h(×2 ~ 6W) | 0.2kW | 0.75kW | 550 ~ 1050kg |

| NP-50-2 ~ 4W | 200L/h(×2 ~ 4W) | 0.75kW | 0.75kW | 950 ~ 1400kg |

| NP-100-2 ~ 4W | 500L/h(×2 ~ 4W) | 0.75kW | 0.75kW | 950 ~ 1400kg |

| NP-200-2 ~ 4W | 2.2M3/h(×2 ~ 4W) | 0.75kW | 1.5kW | 1200 ~ 1750kg |

| NP-300-2 ~ 4W | 5.5M3/h(×2 ~ 4W) | 1.5kW | 2.2kW | 2300 ~ 3300kg |

| NP-400-2 ~ 4W | 13M3/h(×2 ~ 4W) | 1.5kW | 3.7kW | 3700 ~ 5500kg |

Applicable Powder Material List for Feeders

Waste disposal plant

| Activated carbon |

| Slaked lime |

| Calcium carbonate |

| Auxiliary agent |

| Bicarbonate |

Lime hydrating and paper production plant

| Pulverized coal |

| Oil cokes |

Cement production plant

| Cement |