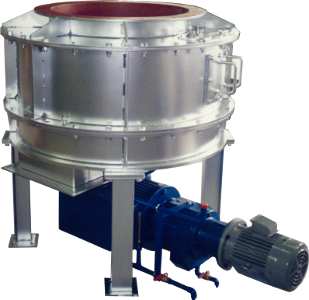

RD / RE / RS Type Ring Feeder

For Wet Cake property material discharge

Features

- Ring Feeder “RD/RE/RS Type” offers design flexibility which can use large hopper opening diameter that exceeds critical arching dimension of the feed material.

- RD/RE/RS is an optimum discharge equipment for difficult to handle bulk materials like irregular shaped material, wet cake property material(e.g. Dry sludge, wood chip, RDF, and cotton) that stored in silos.

RD Type Details

【Features】

Makes the Feeding of Highly Adhesive Wet Powders Possible

Ring Feeder “RD Type” is an optimum discharge equipment for difficult to handle bulk materials stored in silos. RD can discharge wet and/or cake property materials stably.

RD can feed highly adhesive material because combination of the unique ring type feeding table and horizontal scraper.

【Structure】

The powder from the upstream equipment(e.g. silo) is stacked in a conical shape on the Bottom Pan③ according to the angle of repose. The Feeding Table with vane⑦ is bring material from Upper Vessel⑨ through the Spout⑤ to the Horizontal Scraper⑧. The powder is continuously discharged from the Chute⑥.

Combination adjust the vertical position of the Spout⑤ with adjust rotation speed by inverter of Feeding Table⑦ gives broad range of feed rate.

RE Type Details

【Features】

Ring Feeder “RE Type” is an optimum discharge equipment for difficult to handle bulk materials stored in silos.

RE can discharge dry, fibrous material, or cotton property materials stably. Because design of the levelling plate and ring type impeller feeding table can customize to fit the material property.

【Structure】

The powder from the upstream equipment (e.g. Silo) is charged to the feeding table in a uniform condition without consolidation by the Agitator⑤.

The powder is leveled by the depth of the impeller of the rotating Feeding Table⑦ and is continuously discharged from the Chute⑥.

Feed rate can be adjusted by changing the motor rotation speed with the inverter.

RS Type Details

【Features】

Ring Feeder “RS Type” is the solution for getting sticky cohesive materials to feed reliably.

Because design of the Scraper and ring type impeller feeding table can customize to fit the material property.

RS is ideal for feed of materials with easy-to-bite at feeding table by its bite detection feature.

RS offering sequential drive such as forward reverse motor control with torque detection. That helps expressly designed to detect feeder jams and/or overload.

【Structure】

The powder from the upstream equipment (e.g. Silo) is charged to the feeding table in a uniform condition without consolidation by the Agitator⑤.

The powder is leveled by the depth of the impeller of the rotating Feeding Table⑦ through the Horizontal Scraper⑧ and is continuously discharged from the Chute⑥.

Feed rate can be adjusted by changing the motor rotation speed with the inverter.

Specification

| Feed rate | Motor Power | Weight | |

|---|---|---|---|

| RD-03 | 1m3/h | 0.4kW | 150kg |

| RD-05 | 2m3/h | 0.75kW | 400kg |

| RD-07 | 5m3/h | 1.5kW | 800kg |

| RD-10 | 10m3/h | 2.2kW | 1500kg |

| RD-12 | 15m3/h | 3.7kW | 1700kg |

| RD-14 | 20m3/h | 3.7kW | 2200kg |

| RD-16 | 25m3/h | 5.5kW | 2700kg |

| RD-18 | 35m3/h | 5.5kW | 3400kg |

| RD-20 | 45m3/h | 7.5kW | 4300kg |

| RD-24 | 60m3/h | 7.5kW | 5500kg |

| Feed rate | Motor Power | Weight | |

|---|---|---|---|

| RS,RE-04 | 0.5m3/h | 0.4kW | 250kg |

| RS,RE-05 | 1m3/h | 0.75kW | 350kg |

| RS,RE-07 | 3m3/h | 1.5kW | 700kg |

| RS,RE-10 | 10m3/h | 2.2kW | 1300kg |

| RS,RE-12 | 15m3/h | 3.7kW | 1500kg |

| RS,RE-14 | 20m3/h | 3.7kW | 1800kg |

| RS,RE-16 | 25m3/h | 5.5kW | 2200kg |

| RS,RE-18 | 35m3/h | 5.5kW | 2800kg |

| RS,RE-20 | 45m3/h | 7.5kW | 3500kg |

| RS,RE-24 | 60m3/h | 7.5kW | 4500kg |

Examples of Applications

Powder Processing Line

Measuring-type Pneumatic-Transport System

Storage and Feeding System

Receiving and Feeding System

Batch Weighing System

Chemical Feeding System

Examples of Applications with RD/RE/RS Type Ring Feeder

RS-07

| Capable of feeding dried sludge from sewage treatment equipment. |

RE-04

| Capable of feeding wood chips in batches at carboneized fuel reserch facilities. |

RE-05

| Capable of feeding additives(carbon fibers) at chemical factories. |

RD-20

| Capable of feeding plaster powder at manufacturing facilities. |

Applicable Powder Material List for Feeders

| Slaked lime | Dewatered sludge |

| Quick lime | Bagasse |

| Cement | Wood chip |

| Wet activated carbon | Refuse derived fuel |

| Calcium carbonate | Rubber |

| Hydrated alumina | Waste plastic |

| Talc | Waste paper |

| Oil cokes | Gypsum board powder |

| Coal compound | Fertilizer |

| Ferrous sulfate | Feed grain |

| Sodium metavanadate | Pulp powder |

| Salt | Dry sludge |

| AL system inorganic substance | Burned ash |

| Jeweler’s rouge | Melted fly ash |

| Activated carbon | Heavy oil ash |