For the Feed of Various Forms of Materials

Continuous Feed is Possible without Deformation of the Material.

Features

- Allows the feed of flake, pellet, powder, cluster, and fiber materials.

- Continuous feed without pulsation is made possible because of its flat type feeding table.

- Forcibly extracts material from inside the feeder, therefore no material remains.

Details

Make-up

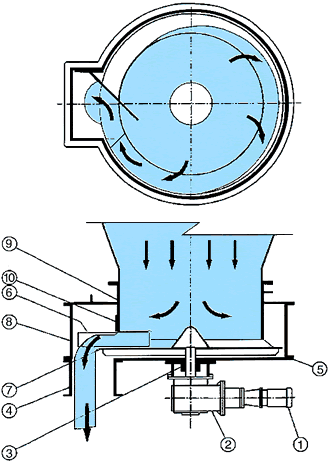

Power or granular material stocked in the Hopper is charged and replaced to the Feeding Table 7 from the Upper Vessel 9 , and is moved along the Scrape Plate 6 and discharged continuously from the Exit Chute 4 . The adjustment of the Feeding Volume is done by the revolution change and the adjustment of the Exit Gate 10 .

| No. | Name |

|---|---|

| 1 | Motor |

| 2 | Reduction Gear |

| 3 | Vertical Shaft |

| 4 | Exit Chute |

| 5 | Bottom Pan |

| 6 | Scrape plate |

| 7 | Feeding Table |

| 8 | Lower Vessel |

| 9 | Upper Vessel |

| 10 | Exit Gate |

Specification

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|

|---|---|---|---|

| T-03 | 500L/h | 0.75kW | 400kg |

| T-05 | 2m3/h | 1.5kW | 700kg |

| T-07 | 5m3/h | 1.5kW | 1100kg |

| T-10 | 10m3/h | 2.2kW | 1700kg |

| T-15 | 30m3/h | 5.5kW | 3200kg |

| T-20 | 50m3/h | 11kW | 5000kg |

| T-24 | 60m3/h | 15kW | 7000kg |