For Equipment that Requires Cleaning on Disassembly

Allows accurate feed even under sanitary specifications.

- One-touch assembly and disassembly allows for easy cleaning and materials switching.

- Because it is possible to select the model to match its intended use and the powder properties, accurate feed even under sanitary specifications is easily achievable.

- This type is adequate for equipment that requires sanitary oversight.

|

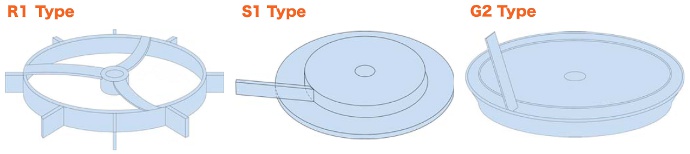

供給盤型式 Feeding Table Type |

切出方式 Leveling System |

用途 Application |

|

|---|---|---|---|

| R1型(Type) |

リングテーブル Ring table |

自然落下式 gravitational |

湿粉粒体 Wet powder |

| S1型(Type) |

ステップテーブル Step table |

スクレーパー式 Scraper |

乾燥粉粒体 Dry powder |

| G2型(Type) |

グルーブテーブル Groove table |

スクレーパー式 Scraper |

付着性粉粒体 Adhesive powder |

- Due to the structure which can feed the powders with the fixed volume of mass, highly accurate, steady, and continuous feeding is possible.

- Stable feeding of highly adhesive wet powders and cakes is possible.

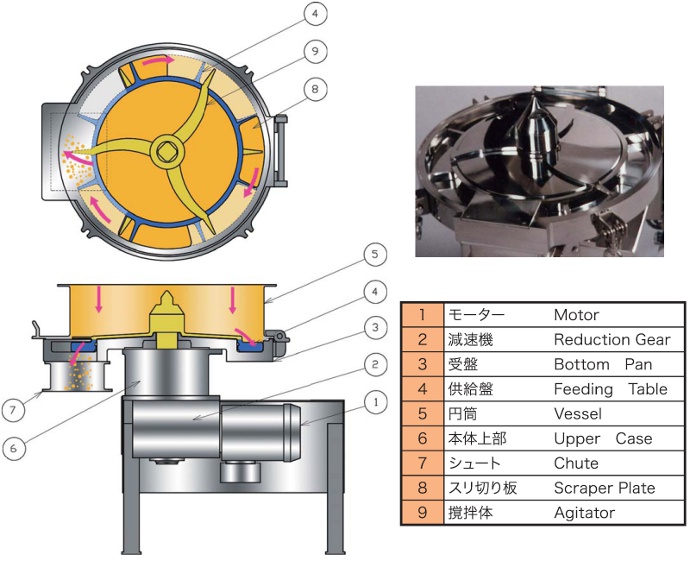

The stored powder or grain materials are deposited inside the feeding table (4) by the agitator (9) with constant density and without compression through the scraper plate (8).

The deposited powder or grains with fixed amount are continuously sent into the chute (7).

A wide range of feed rate settings are possible by altering the rotation speed of the feeding table at the inverter.

- Continuous feeding is possible without deforming the grains of powders, flakes, and pellets and with less biting/abrasion.

- As powders deposited into the feeding table are continuously scooped by the scraper, continuous feeding without pulsation is made possible.

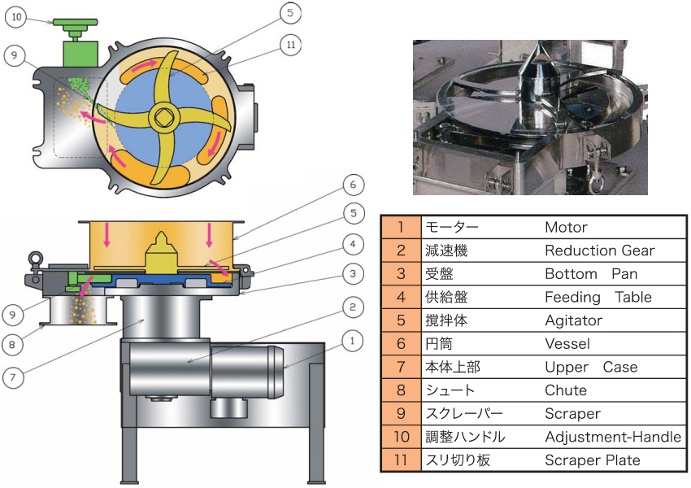

The stored powder or grain materials are deposited inside the feeding table (4) by the agitator (5) with constant density and without compression through the scraper plate (11).

The deposited powder or grains with fixed amount are scooped out continuously with the scraper (9), and then sent into the chute (8).

Adjustment of the feed rate is performed by varying rotation speed at the inverter.

A wide range of feed rate settings are possible through the scraper adjustment handle (10) (optional).

- As this feeder is constructed to use the scraper to forcibly scoop even small amounts of adhesive powder or grain materials, stable feeding is possible.

- Due to that two drive shafts are applied to the feeding table drive and the agitator drive individually (twin drive shaft system). the feeder inlet diametercan be widened allowing even small amount ofpowder or grain materials to be fed without the occurrence of bridging.

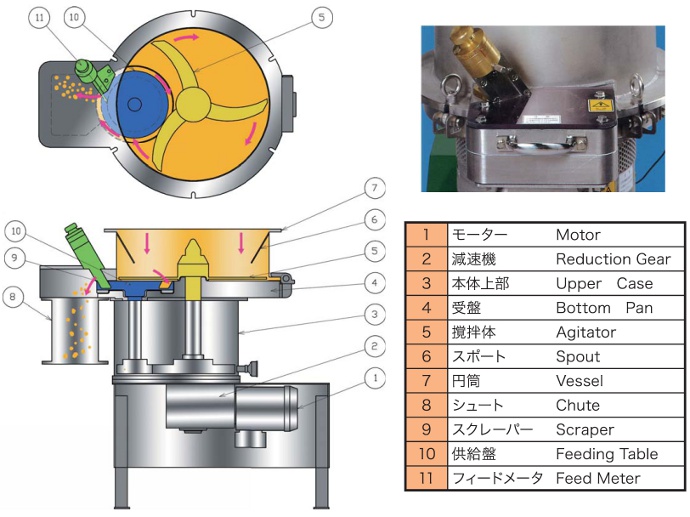

With the spout (6) (powder pressure reducing device) at feeder inlet (7) and the agitator (5), stored powder or grain materials are deposited inside the feeding table (10) with constant density and without compression.

The deposited powder or grains with fixed amount are scooped out continuously with the scraper (9), and then sent into the chute (8).

A wide range of feed rate settings are possible through joint adjustments to the scraper position (9) and by altering the rotation speed of the feeding table at the inverter.

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|

|---|---|---|---|

| R1-04 | 500L/h | 0.4kW | 190kg |

| R1-05 | 1000L/h | 0.75kW | 270kg |

| S1-03 | 500L/h | 0.4kW | 160kg |

| S1-04 | 1100L/h | 0.75kW | 190kg |

| S1-05 | 2300L/h | 0.75kW | 270kg |

| G2-03 | 50L/h | 0.2kW | 200kg |

| G2-04 | 150L/h | 0.4kW | 220kg |

| G2-05 | 400L/h | 0.75kW | 290kg |

Applicable Powder Material List for Feeders

| R1 Type Ring Table | |||

|---|---|---|---|

| お茶粉 | Tea powder | 活性炭 | Activated carbon |

| 顔料 | Pigment | 脱水ケーキ | Dehydrated cake |

| 有機飼料 | Organic feed | 乾操汚泥 | Dried sludge |

| 肥料 | Fertilizer | ||

| S1 Type Step Table | |||

|---|---|---|---|

| 食塩 | Salt | ペレット | Pellet |

| 砂 | Sand | フレーク原料 | Flake type material |

| ガラスピーズ | Glass beads | 顆粒原料 | Granular material |

| グラックス | Flax | ||

| G2 Type Groove Table | |||

|---|---|---|---|

| 小麦粉 | Flour | ワックス | Wax |

| だしの素 | Seasoning | シリ力 | Silica |

| ビスフェノール | Bisphenol | クレー | Clay |

| タルク | Talc | ベンガラ | Jeweler’s rouge |