Multi-Feed Pneumatic Transport

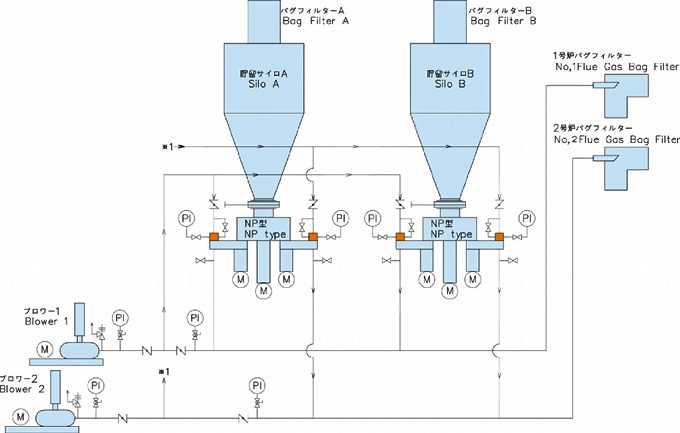

Multi-Feed Pneumatic Quantitative Transport from One Silo.

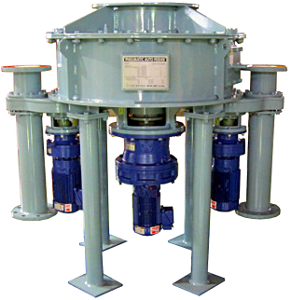

Our pneumatic auto feeders are highly reliable quantitative pneumatic table feeders used for the transportation of powder or grain materials.

The feeders perform continuous high-accurate volumetric feeding (blowing) to the next stage of a process line.

Powder or grains are fed directly through pneumatic transportation piping, thus allowing controlled, adhesion-free transportation.

This earned our feeders a reputation of being ‘the standard for quantitative pneumatic feeding’ and are used widely used in a wide range of industries.

Our broad assortment, including the PS Type (Single-feed), the NP Type (Multi-feed) and the NPS Type (for Micro feed rate), allows you to choose a feeder that is suited to the specific needs of your plant.

1. Realizes Multi-Directional Quantitative Feeding (Blowing)

This equipment realizes stable quantitative feeding (blowing) in multiple directions (2-6 directions) from a single silo.

2. Capable of Individual Feed Rate Adjustment

As the feeding mechanism and agitator are independent, it is possible to adjust the feed rate to correspond to the rates necessary at each individual feeding structure module.

3. Capable of Combining Pneumatic Transport and Gravity Transport Methods

As each feeding mechanism is independent, it is possible to simultaneously operate both pneumatic transport and gravity transport methods at a single silo.

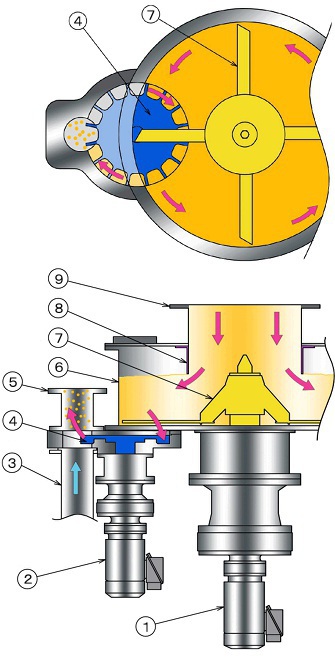

Make-up

Accumulated powders are filled into the feeding table mass (4) in a non-compacted, uniform and finely-crumbled state through the spout (8) located at the entrance of the feeder vessel (powder de-compacting mechanism) and the agitator (7).

Powders filled into the feeding table mass (4) are cut into uniform volumes, after which they are fed into the transport piping (5) and are pneumatically transported with stability.

The feed rate can be adjusted by altering the rotation speed of the feeding table at the invertor.

| 1 | 撹拌用モーター | Agitator Motor |

| 2 | 供給用モーター | Feeder Motor |

| 3 | 輸送配管 | Inlet |

| 4 | 供給盤 | Feeding Table |

| 5 | 輸送配管 | Outlet |

| 6 | 撹拌筒 | Agitator Vessel |

| 7 | 撹拌体 | Agitator |

| 8 | スポート | Spout |

| 9 | 投入口 | Inlet Pipe |

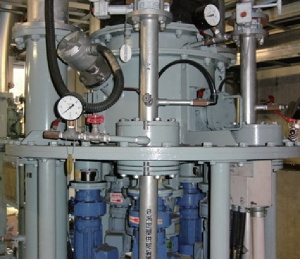

Pressure Balancer (Patent Number 3803040)

We offer the best solutions to prevent trouble, combing a wide variety of design plans.

If the pressure inside the transport piping at the feeder exit greatly exceeds the powder seal pressure inside the silo, there is a possibility that the pressure balance required for stable pneumatic transport will be disrupted and air injected into the inside of the feeder, impacting quantitative feeding functionality. There is also a possibility that flushing into other system’s transport piping will be induced.

We has developed a Pressure Balancer that contains a mechanism that adjusts the internal transport tube pressure in the transport piping to the correct value. The Pressure Balancer makes use of the total of air extensive experience and accomplishments and has been exhaustively tested in-house.

The Pressure Balancer uses the ejection effect to lower the pressure of the interior of the transport piping, and is a device that is capable to adjusting the pressure to the correct value.

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

||

|---|---|---|---|---|

|

供給機 Feeder Motor |

撹拌機 Agitator Motor |

|||

| NP-30-2 ~ 6W | 70L/h(×2 ~ 6W) | 0.2kW | 0.75kW | 550 ~ 1050kg |

| NP-50-2 ~ 4W | 200L/h(×2 ~ 4W) | 0.75kW | 0.75kW | 950 ~ 1400kg |

| NP-100-2 ~ 4W | 500L/h(×2 ~ 4W) | 0.75kW | 0.75kW | 950 ~ 1400kg |

| NP-200-2 ~ 4W | 2.2M3/h(×2 ~ 4W) | 0.75kW | 1.5kW | 1200 ~ 1750kg |

| NP-300-2 ~ 4W | 5.5M3/h(×2 ~ 4W) | 1.5kW | 2.2kW | 2300 ~ 3300kg |

| NP-400-2 ~ 4W | 13M3/h(×2 ~ 4W) | 1.5kW | 3.7kW | 3700 ~ 5500kg |

Applicable Powder Material List for Feeders

| 活性炭 | Activated carbon |

| 消石灰 | Slaked lime |

| 炭酸カルシウム | Calcium carbonate |

| 特殊反応助剤 | Auxiliary agent |

| 重曹 | Bicarbonate |

| 微粉炭 | Pulverized coal |

| オイルコークス | Oil cokes |

Cement production plant

| セメント | Cement |