Continuous Feed Without Pulsation

Even with only a small amount of adhesive powder this machine provides continuous feed with no pulsation.

The actualization of continuous feeding without pulsation

As powders deposited into the feeding table are continuously scooped by the scraper, continuous feeding without pulsation is made possible.

A wide range of feed rate settings are possible

By also adjusting the inverter and scraper depth, a wide range of feed rate settings are possible.

Stable feeding is possible even for adhesive powders

As this feeder is constructed to use the scraper to forcibly scoop even small amounts of adhesive powders, stable feeding is possible.

No bridging

Due to that two drive shafts are applied to the feeding table drive and the agitator drive individually (twin drive shaft system),

the feeder inlet diameter can be widened allowing even small amount of powder to be fed without of bridging.

The actualization of accurate feeding

As this feeder is constructed to use the spout (powder pressure reducing device) to prevent of powder compression, fluctuations in bulk density can be minimized.

As a result accurate feeding is possible.

Outline

The Smooth Auto Feeder (CF-type) is a quantitative feeder that has a unique two-axle feed method as well as a groove feeding table/scraper attached to the feeding unit to enable a consistent, continuous feed.

By using a scraper to forcibly trim off powder loaded onto the feeding table, this machine provides stable, continuous feeding to the next process even if the powder is somewhat adhesive.

With the technology and trust we have built up over half a century of doing business, we have developed a proven track record with countless fulfilled orders from many industries, and are well-loved for our “Consistent, Accurate Quantitative Feeders”

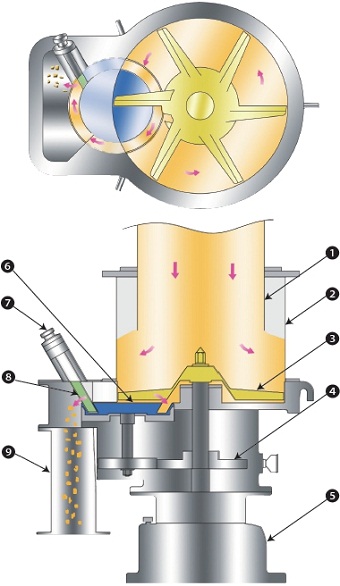

Make-up

With the spout (1) (powder pressure reducing device) at feeder inlet and the agitator (3), stored powder or grain materials are deposited inside the feeding table (6) with constant density without compression.

The deposited’ powder or grains with fixed amount are scooped out continuously with the scraper (8), and then fed into the chute (9).

Wide ranges of feed rate are possible by adjusting the scraper (8) position and altering the rotation speed of the feeding table by inverter.

| 1 | スポート | Spout |

| 2 | 下部円筒 | Lower Vessel |

| 3 | 撹拌体 | Agitator |

| 4 | スパーギヤ | Spur Gear |

| 5 | 減速機 | Reduction Gear |

| 6 | 供給盤 | Feeding Table |

| 7 | フィードメータ | Feed Meter |

| 8 | スクレーパー | Scraper |

| 9 | シュート | Chute |

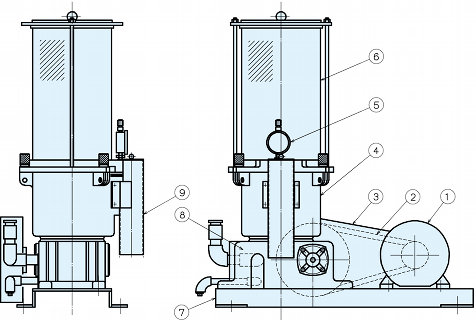

For equipment requiring feed rate for 0.85cc/min

| 1 | モーター | Motor |

| 2 | Vベルト | V Belt |

| 3 | ベルトカバー | Belt Cover |

| 4 | 受盤 | Bottom Pan |

| 5 | フィードメータ | Feed Meter |

| 6 | アクリル円筒 | Acryl Vessel |

| 7 | コモンベッド | Common Bed |

| 8 | 減速機 | Reduction Gear |

| 9 | シュート | Chute |

|

型式 Type |

型式分類 Class |

供給量 (Max) Feed rate |

モーター出力 Moter Power |

円筒容量 Vessel Volume |

概略重量 Weight |

|---|---|---|---|---|---|

| CF-50 | CF-52 | 1 L/h | 0.2 kW | 4 L | 30 kg |

| CF-53 | 2 L/h | 0.2 kW | 4 L | 30 kg |

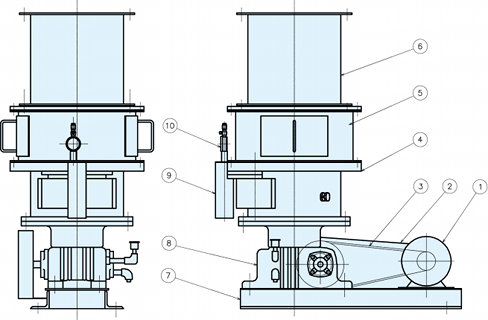

For equipment requiring the small feed rate for powder like additives

| 1 | モーター | Motor |

| 2 | ベルトカバー | Belt Cover |

| 3 | Vベルト | V Belt |

| 4 | 受盤 | Bottom Pan |

| 5 | 下部円筒 | Lower Vessel |

| 6 | 上部円筒 | Upper Vessel |

| 7 | コモンベッド | Common Bed |

| 8 | 減速機 | Reduction Gear |

| 9 | シュート | Chute |

| 10 | フィードメータ | Feed Meter |

|

型式 Type |

型式分類 Class |

供給量 (Max) Feed rate |

モーター出力 Moter Power |

概略重量 Weight |

|---|---|---|---|---|

| CF-100 | CF-103 | 2.9 L/h | 0.2 kW | 50 kg |

| CF-105 | 6 L/h | |||

| CF-200 | CF-203 | 6 L/h | 0.4 kW | 70 kg |

| CF-205 | 12 L/h | |||

| CF-300 | CF-308 | 48 L/h | 0.75 kW | 90 kg |

| CF-310 | 75 L/h | |||

| CF-312 | 105 L/h | |||

| CF-315 | 130 L/h |

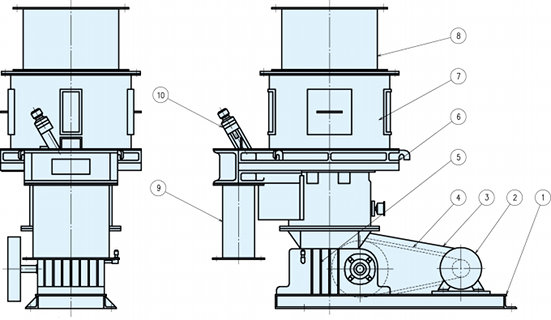

For equipment requiring precision, stable feeding without pulsation

| 1 | コモンベッド | Common Bed |

| 2 | モーター | Motor |

| 3 | ベルトカバー | Belt Cover |

| 4 | Vベルト | V Belt |

| 5 | 減速機 | Reduction Gear |

| 6 | 受盤 | Bottom Pan |

| 7 | 下部円筒 | Lower Vessel |

| 8 | 上部円筒 | Upper Vessel |

| 9 | シュート | Chute |

| 10 | フィードメータ | Feed Meter |

|

型式 Type |

型式分類 Class |

供給量 (Max) Feed rate |

モーター出力 Moter Power |

概略重量 Weight |

|---|---|---|---|---|

| CF-500 | CF-510 | 90 L/h | 1.5 kW | 380 kg |

| CF-515 | 200 L/h | |||

| CF-520 | 300 L/h | |||

| CF-528 | 600 L/h | |||

| CF-535 | 900 L/h | |||

| CF-600 | CF-630 | 1.0 m3/h | 2.2 kW | 510 kg |

| CF-640 | 1.5 m3/h | |||

| CF-655 | 3.0 m3/h | |||

| CF-700 | CF-740 | 1.9 m3/h | 3.7 kW | 680 kg |

| CF-755 | 3.6 m3/h | |||

| CF-770 | 6.0 m3/h | |||

| CF-800 | CF-890 | 15.0 m3/h | 5.5 kW | 1000 kg |

|

all-stainless construction allow to feed corrosive powder. |

|

Capable of pneumatic transporting for small volumes of powders with the ejector. |

|

Capable of powder feeding from the flexible container bag. |

|

Capable of stable feed rate control with weighing system. |

Applicable Powder Material List for Feeders

| 消石灰 | Slaked lime | ポリエチレン | Polyethylene |

| 炭酸カルシウム | Calcium carbonate | 重曹 | Sodium bicarbonate |

| 活性炭 | Activated carbon | フッカアルミニウム | Aluminum fluoride |

| セメント | Cement | シリカ | Silica |

| 珪藻土 | Diatomite | カーボン | Carbon |

| フライアッシュ | Fly ash | ポリマー | Polymer |

| ソーダ灰 | Soda ash | 酸化チタン | Titanium oxide |

| フラックス | Flux | タルク | Talc |

| 微粉炭 | Galvanized coal | クレー | Clay |

| アルミナ | Aluminum | ベントナイト | Bentonite |

| 小麦粉 | Flour | 亜鉛粉末 | Zinc powder |

| 砂糖 | Sugar | ステアリン酸 | Stearic acid |

| 食塩 | Salt | メチルセルロース | Methyl cellulose |

| 澱粉 | Starch | クエン酸 | Citric acid |

| 酵母 | Yeast | ビタミン剤 | Vitamin powder |

| ワックス | Wax | マグネシウム | Magnesium |

| ベンガラ | Jeweler’s rouge | JIS ダスト | JIS Dust |

| 米粉 | Rice powder | トナー | Toner |

| 炭酸バリウム | Barium carbonate | ニッケル | Nickel |