Single-Feed Pneumatic Transport

The realization of research and large-scale equipment quantitative pneumatic transport.

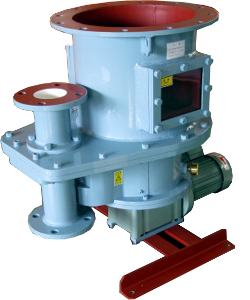

Our pneumatic auto feeders are highly reliable quantitative pneumatic table feeders used for the transportation of powder or grain materials.

The feeders perform continuous high-accurate volumetric feeding (blowing) to the next stage of a process line.

Powder or grains are fed directly through pneumatic transportation piping, thus allowing controlled, adhesion-free transportation.

This earned our feeders a reputation of being ‘the standard for quantitative pneumatic feeding’ and are used widely used in a wide range of industries.

Our broad assortment, including the PS Type (Single-feed), the NP Type (Multi-feed) and the NPS Type (for Micro feed rate), allows you to choose a feeder that is suited to the specific needs of your plant.

1. Realizes High Accurate Quantitative Feeding (Blowing).

This equipment realizes high feeding accurate and stable blowing through its individual powder mass volume measuring structure.

2. Realizes Stable Quantitative Feeding (Blowing) Even During Long Operation Periods

As the feed mechanism is continually cleaned by the transport air, stable blowing over long operation periods is realized.

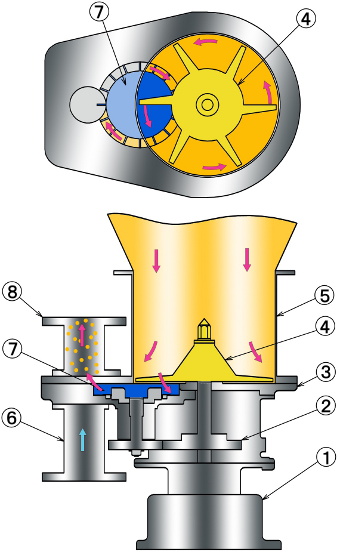

Make-up

Accumulated powders are filled into the feeding table (7) from the agitator (4) in a uniform state with no compaction.

Powders fed into the feeding table (7) are cut into uniform volumes, after which they are fed into the transport piping (5) and are pneumatically transported with stability.

The inverter can vary the rotation speed to adjust feed rate.

| 1 | 減速機 | Reduction Gear |

| 2 | スパーギヤ | Spur Gear |

| 3 | 受盤 | Bottom Pan |

| 4 | 撹拌体 | Agitator |

| 5 | 下部円筒 | Lower Vessel |

| 6 | 輸送配管 | Inlet |

| 7 | 供給盤 | Feeding Table |

| 8 | 輸送配管 | Outlet |

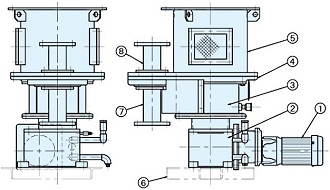

Motor direct connection Single-feed PSD Type

| 1 | モーター | Motor |

| 2 | 減速機 | Reduction Gear |

| 3 | 本体上部 | Upper Case |

| 4 | 受盤 | Bottom Pan |

| 5 | 下部円筒 | Lower Vessel |

| 6 | 輸送用ベース | Base |

| 7 | 輸送配管 | Inlet |

| 8 | 輸送配管 | Outlet |

| PS |

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|---|---|---|---|

| PS-100 | 20L/h | 0.2kW | 100kg |

| PS-200 | 60L/h | 0.2kW | 110kg |

| PS-300 | 300L/h | 0.4~0.75kW | 185kg |

| PS-500 | 900L/h | 1.5kW | 500kg |

| PS-600 | 3.0M3/h | 2.2kW | 600kg |

| PS-700 | 6.0M3/h | 3.7kW | 800kg |

| PSD |

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|---|---|---|---|

| PSD-300 | 300L/h | 0.2~0.4kW | 185kg |

| PSD-500 | 900L/h | 0.75kW | 500kg |

| PSD-600 | 3.0M3/h | 1.5kW | 600kg |

| PSD-700 | 6.0M3/h | 2.2kW | 800kg |

Applicable Powder Material List for Feeders

| 活性炭 | Activated carbon |

| 消石灰 | Slaked lime |

| 炭酸カルシウム | Calcium carbonate |

| 特殊反応助剤 | Auxiliary agent |

| 重曹 | Bicarbonate |

| 微粉炭 | Pulverized coal |

| オイルコークス | Oil cokes |

Cement production plant

| セメント | Cement |