Single-Feed Pneumatic Transport

The realization of research and large-scale equipment quantitative pneumatic transport.

Our pneumatic auto feeders are highly reliable quantitative pneumatic table feeders used for the transportation of powder or grain materials.

The feeders perform continuous high-accurate volumetric feeding (blowing) to the next stage of a process line.

Powder or grains are fed directly through pneumatic transportation piping, thus allowing controlled, adhesion-free transportation.

This earned our feeders a reputation of being ‘the standard for quantitative pneumatic feeding’ and are used widely used in a wide range of industries.

Our broad assortment, including the PS Type (Single-feed), the NP Type (Multi-feed) and the NPS Type (for Micro feed rate), allows you to choose a feeder that is suited to the specific needs of your plant.

1. Stable Pneumatic Transport is Possible Even for Micro Volume Feeding

The individual powder mass volume measuring structure of this equipment realizes high-accurate feeding and pneumatic transport with small amounts of carrier gas.

2. Easy Disassembly and Cleaning are Possible

Connecting parts are easy disassembled, allowing for easy cleaning of the inside of the equipment.

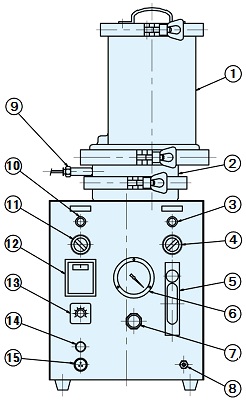

| 1 | ホッパー | Hopper |

| 2 | フィーダー | Feeder |

| 3 | ON/OFFランプ | ON/OFF lamp |

| 4 | 電源スイッチ | Power switch |

| 5 | 圧力計 | Pressure gauge |

| 6 | 流量計 | Flow meter |

| 7 | 減圧弁 | Pressure reduction valve |

| 8 | ガス供給口 | Gas inlet |

| 9 | パウダー出口 | Powder outlet |

| 10 | 電源ランプ | Power lamp |

| 11 | メカニカルバルブ | Mechanical valve |

| 12 | 回転計 | Tachometer |

| 13 | 回転数設定ボリューム | Revolution adjusting volume |

| 14 | ヒューズ | Fuse |

| 15 | 電源コネクター | Power connector |

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|

|---|---|---|---|

| NPS-50 | 0.01 ~ 2.0L/h | 90W | 60kg |

| NPS-200 | 0.4 ~ 12.0L/h | 0.2kW | 170kg |

Applicable Powder Material List for Feeders

Melting furnace and research plant

| 酸化チタン | Titanium |

| フラックス | Flux |

| シリカ | Silica |

| セラミックス | Ceramics |