For Various Kinds of Dry Powders

This machine provides a stable feed of various kinds of dry powders.

Stable feeding of a wide variety of dry powders

Our feeders scrape powder from a container and batch it by volume, which allows for high accurate, stable feeding for a wide variety of dry powders.

Suitable for high fluid powder feeding as well

Use of our tightly sealed Encircle Disc allows for stable feeding of highly fluid powders as well.

Allows for high accurate feeding

Use of a spout (powder-pressure reducing device) enables high accurate feeding thanks to its special construction that is unaffected by highly variable specific gravity from the powder pressure.

Handles adhesive and firmly adhesive powders

The unit is constructed for different powder properties for stable feeding of fly ash and other adhesive powders, and cement, sodium bicarbonate, and other firmly adhesive powders.

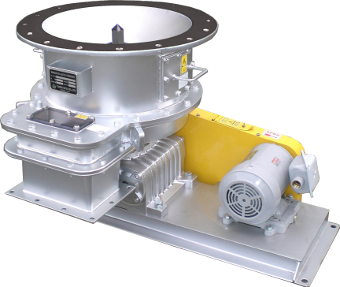

The ELCF Type Smooth Auto Feeder is a highly reliable quantitative feeder that continuously and accurately feeds powder or grain to the next process.

Its use of a tight-sealing Encircle-Disc (scrapes powders and grain from a container and batches them by volume) allows for stable supply of even highly-fluid powders.

Our reliability and expertise, cultivated for over 50 years, can be found in each and every one of our products.

Our feeders enjoy high praise in pollution control facilities; the chemicals industry; the steel, refining, and metals industries; the paper industry; the food industry; and numerous other industries.

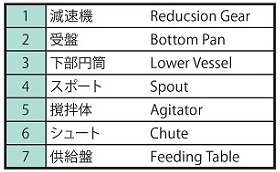

Make-up

The accumulated powder is kept at a set powder pressure in the spout (4) (powder-pressure reducing device) installed at inlet in the lower vessel (3).

It is then deposited inside the feeding table (7) in a homogenous, uncompressed state by the agitator.

The powder deposited inside the feeding table (7) is scraped to a set volume, and then fed to the chute (6).

The inverter can vary the rotation speed to adjust feed rate.

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|

|---|---|---|---|

| ELCF-50 | 300L/h | 0.4kW | 120kg |

| ELCF-100 | 600L/h | 0.75kW | 200kg |

| ELCF-200 | 3m3/h | 1.5kW | 350kg |

| ELCF-300 | 6.5m3/h | 2.2kW | 600kg |

| ELCF-400 | 15m3/h | 3.7kW | 1000kg |

| ELCF-500 | 40m3/h | 5.5kW | 1400kg |

| ELCF-600 | 80m3/h | 7.5kW | 2300kg |

| ELCF-700 | 160m3/h | 11kW | 3300kg |

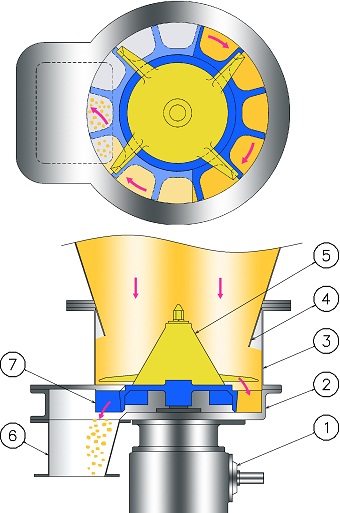

Automatic Dissolution System

Our feeders are used for feeding of chemicals (powders) into dissolving tanks,

which need reliable concentration control, in dissolution equipment, such as factory drainage treatment/neutralization equipment and other water treatment equipment at treatment plants.

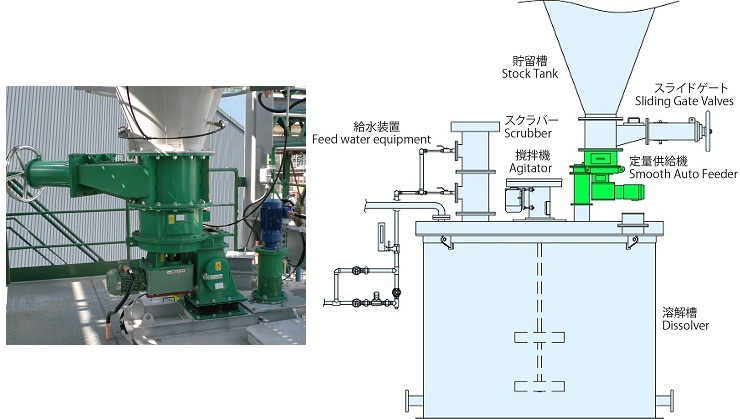

Fly Ash Feeding System

At waste incineration facilities, they find use as quantitative reliable feeders for feeding fly ash to the next process

(solidification in ash beds).

Applicable Powder Material List for Feeders

| 消石灰 | Slaked lime | 炭酸ストロンチュウム | Strontium carbonate |

| 炭酸カルシウム | Calcium carbonate | 硫酸ニッケル | Nickel sulfate |

| 活性炭 | Activated carbon | 炭酸ニッケル | Nickel carbonate |

| 反応助剤 | Auxiliary agent | 澱粉 | Starch |

| セメント | Cement | ポリエチレン | Polyethylene |

| 珪藻土 | Diatomite | ポリアクリルアマイド | Polyacrylamide |

| ゼオライト | Zeolite | 苛性ソーダ | Caustic soda |

| 尿素 | Urea | 重曹 | Sodium bicarbonate |

| 芒硝 | Glaubers salt | フッカアルミニウム | Aluminium fluoride |

| フライアッシュ | Fly ash | ホウ酸 | Boric acid |

| 焼却灰 | Burned ash | ゼラチン | Gelatin |

| 溶融飛灰 | Melted fly ash | シリカ | Silica |

| ソーダ灰 | Soda ash | カーボン | Carbon |

| 重油灰 | Heavy oil ash | ポリマー | Polymer |

| 酸化鉄 | Ferric oxide | 酸化チタン | Titanium oxide |

| 亜鉛 | Zinc | ビスフェノール | Bisphenol |

| フラックス | Flux | タルク | Talc |

| 微粉炭 | Galvanized coal | ハイドロサルファイト | Hydrosulfite |

| オイルコークス | Oil cokes | カオリン | Kaolin |

| 鉄粒 | Iron granulates | クレー | Clay |

| 酸化クロム | Chromic oxide | 亜硫酸ソーダ | Sulfite soda |

| コバルト | Cobalt | 硫酸マグネシウム | Magnesium sulfate |

| 硅砂 | Silica sand | ゴーセノール | Gohsenol |

| 炭酸亜鉛 | Zinc carbonate | カーバイド | Carbide |

| アルミナ | Aluminum | ドロマイト | Dolomite |