Multi-Feed from the One Silo

Individual feed rate alignment for downward-flow equipment.

Can accurately feed a wide variety of dry powder

Our feeders scrape powders from a container and batch it by volume, which allows for high accurate, stable feeding for a wide variety of dry powders.

Allows steady feeding of highly fluid powder

With tightly sealed Encircle Disc allows stable feeding of highly fluid powder as well.

Allows combination of the pneumatic conveyance method and natural fall method

Because the pneumatic conveyance method and natural fall method can be combined into one system, a wide-range of responses depending on equipment specifications are possible.

Outline

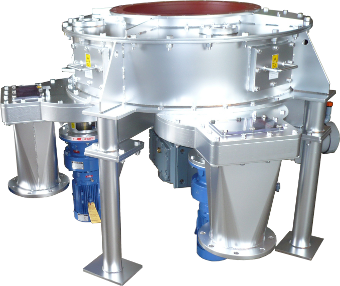

The Smooth Auto Feeder (ST-type) is a multidirectional quantitative feeder which enables continuous powder feeding from a storage silo to multiple directions (2-4 directions).

Can be adjusted in this feeder, because the agitator unit and the various feeding units are independent, feed rate s conforming to downstream equipment and the space required for install at on can be minimized.

Additionally, because it’s a multidirectional feeder, by selecting the feed unit based on powder properties, both natural fall method and pneumatic conveyance method are possible.

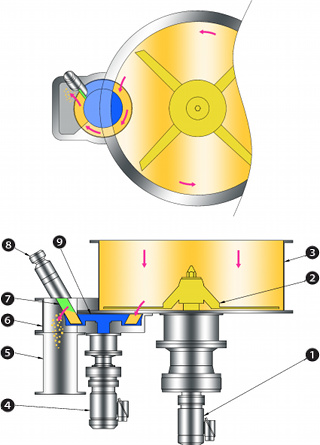

Make-up

With the spout (4) (powder pressure reducing device) at feeder inlet and the agitator (2), stored powder or grain materials are deposited inside the feeding table (9) with constant density and without compression.

Powders fed in this manner are divided into uniform volumes by the scraper plate and are then discharged into the chute (6).

Adjustment of the feed rate is performed by varying rotation speed at the inverter.

| 1 | 撹拌用モーター | Agitator Motor |

| 2 | 撹拌体 | Agitator |

| 3 | 撹拌筒 | Agitator Vessel |

| 4 | スポート | Spout |

| 5 | 供給用モーター | Feeder Motor |

| 6 | シュート | Chute |

| 7 | 供給盤受 | Feeding Table |

| 8 | スリ切り板 | Scraper Plate |

| 9 | 供給盤 | Feeding Table |

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

||

|---|---|---|---|---|

|

供給機 Feeder Motor |

撹拌機 Agitator Motor |

|||

| STECF-50-2 ~ 4W | 200L/h(×2 ~ 4W) | 0.75kW | 0.75kW | 950 ~ 1400kg |

| STECF-100-2 ~ 4W | 500L/h(×2 ~ 4W) | 0.75kW | 0.75kW | 950 ~ 1400kg |

| STECF-200-2 ~ 4W | 2.2m3/h(×2 ~ 4W) | 0.75kW | 1.5kW | 1200 ~ 1750kg |

| STECF-300-2 ~ 4W | 5.5m3/h(×2 ~ 4W) | 1.5kW | 2.2kW | 2300 ~ 3300kg |

| STECF-400-2 ~ 4W | 13m3/h(×2 ~ 4W) | 1.5kW | 2.2kW | 3700 ~ 5500kg |

STCF-100S-2W

|

STECF-200N-3W

|

STRM-5W

|

|

In rechargeable battery manufacturing process, our feeders are being used for feeding highly adhesive powder.

|

In incineration plant, our feeders are used for producing slurry blowing chemicals.

|

In equipment for blowing of supplementary fuels, our feeders are used as distributors to weighing machine.

|

| 消石灰 | Slaked lime | ポリエチレン | Polyethylene |

| 炭酸カルシウム | Calcium carbonate | 重曹 | Sodium bicarbonate |

| 活性炭 | Activated carbon | フッカアルミニウム | Aluminum fluoride |

| セメント | Cement | シリカ | Silica |

| 珪藻土 | Diatomite | カーボン | Carbon |

| フライアッシュ | Fly ash | ポリマー | Polymer |

| ソーダ灰 | Soda ash | 酸化チタン | Titanium oxide |

| フラックス | Flux | タルク | Talc |

| 微粉炭 | Galvanized coal | クレー | Clay |

| アルミナ | Aluminum | ベントナイト | Bentonite |

| 樹脂ペレット | Resin pellet | 亜鉛粉末 | Zinc powder |

| 溶融飛灰 | Melted fly ash | メチルセルロース | Methyl cellulose |

| 焼却灰 | Burned ash | 尿素 | Urea |

| 二酸化マンガン | Manganese dioxide | 苛性ソーダ | Caustic soda |

| 乾燥汚泥 | Dried sludge | 酸化鉄 | Ferric oxide |

| 塩化カリウム | Potassium chloride | 生石灰 | Calcium oxide |

| 過硫酸アンモニウム | Ammonium persulfate | 澱粉 | Starch |

| 重油灰 | Heavy oil ash | カオリン | Kaolin |

| ビスフェノール | Bisphenol | カルボキシメチル | Carboxymethyl |

| オイルコークス | Oil cokes | ハイドロサルファイト | Hydrosulfite |