For Wet and Cake Powders

Allows the stable feed of powders difficult to feed and expel.

- By increasing the entrance diameter, stable feed is possible without bridging.

- Because it is possible to select the model based on the requirements of powder properties, this type can also be used for dry powder.

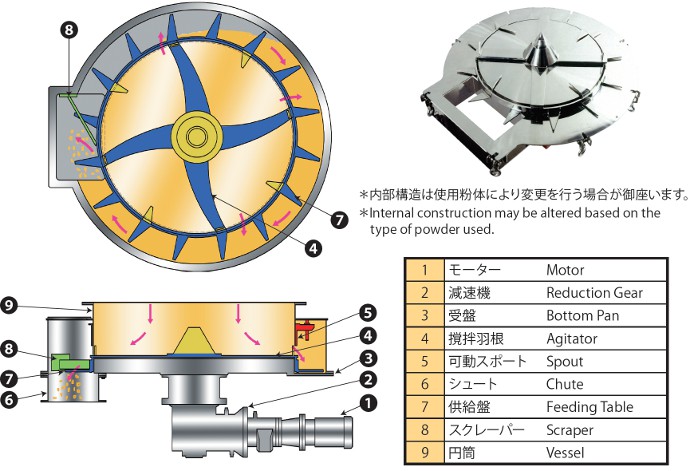

Makes the Feeding of Highly Adhesive Wet Powders Possible

Through the combined use of the special-configuration ring feeding table and the scraper no revolving on the feeding table occurs, making stable feeding of highly-adhesive wet powders possible.

Retained powder are separated by the agitator (4) and in a non-compacted state are filled from the spout aperture (5) to the feeding table (7).

Filled powder are moved to the chute (6), where the scraper (7) forcibly cuts the powder into the chute (6).

Adjustment of the feed rate is performed through variations in the rotation speed through spout adjustments (5) and the inverter.

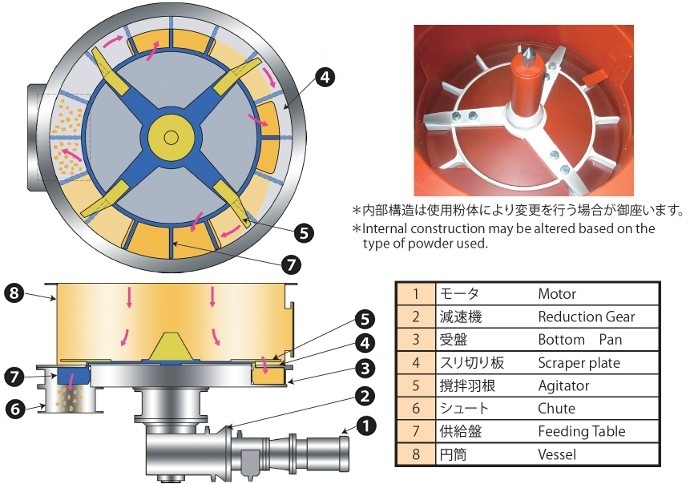

Makes Possible the Stable Feeding of Powders Difficult to Expel and Feed

The combination of the scraper plate aperture being set to the characteristics of the powders and the ring-type feeding table makes possible the stable feeding of difficult powders from dry powders to fibrous and spongy materials.

Retained powder are separated by the agitator (5) and in a non-compacted state are filled from the scraper plate (4) to the feeding table (7).

Filled powder are cut to a fixed volume and are continuously feed to the chute (6).

Adjustment of the feed rate is performed by varying rotation speed at the inverter.

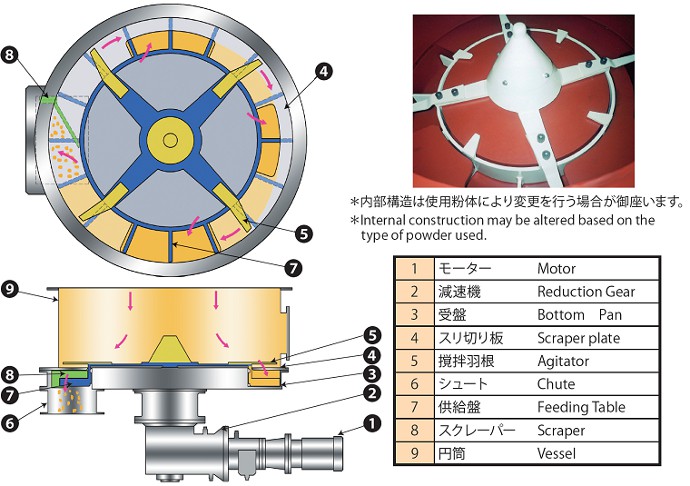

Makes Possible the Expulsion and Feeding of Irregularly Shaped Raw Materials and Cake Powders

Through the combined use of the ring-type feeding table and scraper, the expulsion and feeding of hard-to-expel irregularly shaped raw materials and cake powders is possible.

Anti-Compacting Function Makes Possible the Stable Feeding of Irregularly Shaped Materials

Performing forward-reverse alternating operation through timed operation or the load torque screening function protects against compaction of the raw materials and allows stable feeding.

(For feeding raw materials such as factory refuse)

Retained powder are separated by the agitator (5) and in a non-compacted state are filled to the feeding table (7) through the scraper plate (4).

Filled powder are cut to a fixed volume, where the scraper (8) forcibly cuts the powder into the chute (6).

Adjustment of the feed rate is performed by varying rotation speed at the inverter.

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|

|---|---|---|---|

| RD-03 | 1m3/h | 0.4kW | 150kg |

| RD-05 | 2m3/h | 0.75kW | 400kg |

| RD-07 | 5m3/h | 1.5kW | 800kg |

| RD-10 | 10m3/h | 2.2kW | 1500kg |

| RD-12 | 15m3/h | 3.7kW | 1700kg |

| RD-14 | 20m3/h | 3.7kW | 2200kg |

| RD-16 | 25m3/h | 5.5kW | 2700kg |

| RD-18 | 35m3/h | 5.5kW | 3400kg |

| RD-20 | 45m3/h | 7.5kW | 4300kg |

| RD-24 | 60m3/h | 7.5kW | 5500kg |

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|

|---|---|---|---|

| RS,RE-04 | 0.5m3/h | 0.4kW | 250kg |

| RS,RE-05 | 1m3/h | 0.75kW | 350kg |

| RS,RE-07 | 3m3/h | 1.5kW | 700kg |

| RS,RE-10 | 10m3/h | 2.2kW | 1300kg |

| RS,RE-12 | 15m3/h | 3.7kW | 1500kg |

| RS,RE-14 | 20m3/h | 3.7kW | 1800kg |

| RS,RE-16 | 25m3/h | 5.5kW | 2200kg |

| RS,RE-18 | 35m3/h | 5.5kW | 2800kg |

| RS,RE-20 | 45m3/h | 7.5kW | 3500kg |

| RS,RE-24 | 60m3/h | 7.5kW | 4500kg |

Applicable Powder Material List for Feeders

| 消石灰 | Slaked lime | 脱水ケーキ | Dewatered sludge |

| 生石灰 | Quick lime | バガス | Bagasse |

| セメント | Cement | 木チップ | Wood chip |

| ウェット活性炭 | Wet activated carbon | RDF | Refuse derived fuel |

| 炭酸カルシウム | Calcium carbonate | ゴム | Rubber |

| 水酸化アルミニウム | Hydrated alumina | 廃プラスチック | Waste plastic |

| タルク | Talc | 古紙 | Waste paper |

| オイルコークス | Oil cokes | 石膏ボード粉 | Gypsum board powder |

| 石炭化合物 | Coal compound | 肥料 | Fertilizer |

| 硫酸第一鉄 | Ferrous sulfate | 飼料添加物 | Feed grain |

| メタバナジン酸アンモニウム | Sodium metavanadate | パルプ粉 | Pulp powder |

| 食塩 | Salt | 乾燥汚泥 | Dry sludge |

| AL 系無機物 | AL system inorganic substance | 焼却灰 | Burned ash |

| ベンガラ | Jeweler’s rouge | 溶融飛灰 | Melted fly ash |

| 活性炭 | Activated carbon | 重油灰 | Heavy oil ash |