For Feeding Without Deformation of Particles

Adequate for the feed of materials prone to sticking and abrasion.

The amount of deformation to the raw materials is extremely minimal.

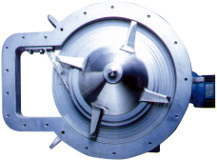

Through the combined use of the step feeding table and scraper, continuous feeding to the next processing step is possible with only minimal compaction or friction occurring within the raw materials.

Continuous feeding without pulsation is possible.

As raw materials fed into the feeding table are continuously cut out by the scraper, continuous feeding without pulsation is made possible.

A wide range of feed rate settings are possible.

Through the combined use of the inverter and the scraper adjustment handle (optional), a wide range of feed rate settings are possible.

Low incidence of bridging.

Due to the fact that two drive shafts are applied to the feeding table drive and the agitator drive individually (twin drive shaft system), the feeder inlet diameter can be widened allowing even small amounts of powders to be fed without the occurrence of bridging.

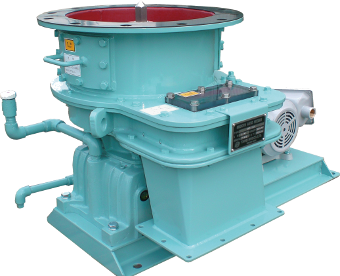

The SGF Type Smooth Auto-Feeder is a quantitative feeder that allows continuous feeding without deforming the shape of powders, flakes, pellets or clusters.

Through the combined use of the step feeding table and scraper, continuous feeding to the next processing step is possible without compaction or friction occurring within the raw materials.

This feeder is widely used in various industries as a “non-pulsating feeder”.

Also, within our lineup there are available the single drive shaft SGF Type and the dual drive shaft CSGF Type Feeders.

Customers can select the type most suited to their needs or our company can make recommendations.

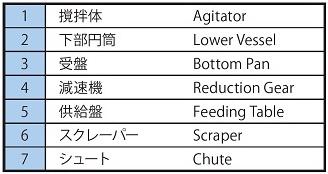

Make-up

The accumulated raw material is filled into the feeding table (5) by the agitator (1) in a non-compacted and uniform state.

After being cut into a fixed volume, the raw material that was filled into the feeding table (5) is sent along the scraper (6) into the chute (7).

Adjustment of the feed rate is performed by varying rotation speed at the inverter.

Furthermore, through the usage of the scraper adjustment handle (optional), an even wider range of feed rate settings are possible.

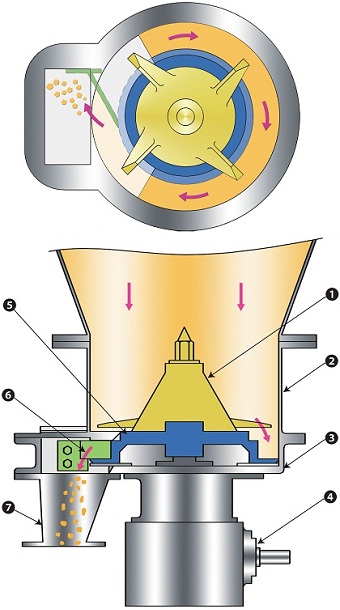

|

供給量(Max) Feed rate |

モーター出力 Motor Power |

概略重量 Weight |

|

|---|---|---|---|

| SGF-50 | 280L/h | 0.4kW | 120kg |

| SGF-100 | 600L/h | 0.75kW | 200kg |

| SGF-200 | 2m3/H | 1.5kW | 350kg |

| SGF-300 | 6m3/H | 2.2kW | 600kg |

| SGF-400 | 13m3/H | 3.7kW | 1000kg |

| SGF-500 | 30m3/H | 5.5kW | 1400kg |

| SGF-600 | 60m3/H | 7.5kW | 2300kg |

| SGF-700 | 150m3/H | 11kW | 3300kg |

| CSGF-10 | 6L/h | 0.2kW | 50kg |

| CSGF-20 | 12L/h | 0.4kW | 75kg |

| CSGF-30 | 130L/h | 0.75kW | 90kg |

Applicable Powder Material List for Feeders

| フラックス | Flux | 石炭 | Coal |

| アルミナ | Aluminum | 乾燥木質活性炭 | Dried wood activated charcoal |

| ワックス | Wax | 塊炭 | Rider coal |

| シリカ | Silica | 焼却灰 | Burned ash |

| 酸化チタン | Titanium oxide | 乾燥汚泥 | Dried sludge |

| 酸化鉄 | Ferrite | 合成ゴム破砕品 | Broken synthetic rubber |

| シアン | Cyanogens | カーボン系微粉 | Carbon minute powder |

| 炭酸ソーダ | Sodium carbonate | 洗剤 | Detergent |

| 黒鉛 | Graphite | 粘土 | Clay |

| 粒状ベンガラ | Granular red oxide | ビスフェノール | Bisphenol |

| 硅砂 | Silica | 肉骨粉 | Meat and bone meal |

| PETレジン | PET resin | 脱脂糖 | Delipidated Sugar |

| 重合防止剤 | Polymerization inhibitor | 尿素 | Urea |

| フェノール樹脂ペレット | Phenolic resin pellet | 球状活性炭 | Spheroidal activated carbon |

| 樹脂ペレット | Resin pellet | フェロボン | Ferroboron |

| 塩ビペレット | Vinyl chloride pellet | AL合金 | Aluminum alloy |

| 合成ゴムペレット | Synthetic rubber pellet | ナイロン | Nylon |

| プラスチックペレット | Plastic pellet | 化学肥料 | Chemical fertilizer |

| SCペレット | Scandium pellet | テトロンフレーク | Tetoron flake |